Johnny Lightning - Topper Toys

Mirror Finish - [1969]

Mirror Finish - [1969]

There are only two questions. Is my car a Mirror?... and if it is... What Color is it?

We will look at both. First is understanding the differences between the two.

MIRROR: A casting with a Costume Jewelry style chrome finish applied before painting.

NON-MIRROR: A casting with it's body highly polished before painting. Sometimes called Near-Mirrors.

Both easily show clear reflections of whats around them.

Non-mirrors many times have clear sharper reflections than do Mirrors.

Mirrors have no imperfections showing underneath the paint as you see through to the plated layer not the Zamac.

Non-mirrors, not having an extra plated layer, show any discoloration(toning) and imperfections in the polished Zamac.

-

-

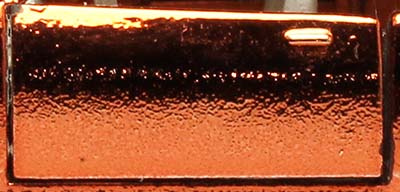

Most mirrors have some texture to their finish. Known as Orange peel.

Non-Mirrors have much smoother paint and none of the orange peel.

Mirrors just reflect light brighter than Non-Mirrors.

-

Again the Orange peel effect on the mirror vs the smooth paint of the non-mirror.

All sides of a mirror car do not have the same amount of orange peel. Some are very smooth while others heavy, but there is always some to be found.

-

Mirrors show no Zamac imperfections as in this door panel

Non-mirrors show all polish lines and discolored areas of the zamac below.

-

Underneath is usually the best place to look to confirm a mirror and it's color.

Mirrors experience alot of UV fade and their true color is best confirmed from underneath.

Mirrors have a bright finish on all sides while non-mirrors were only polished on top.

Three areas to check: 1-Inside the wheel wells, mirrors will be fully painted and bright.

2-Bottom edge of both body sides, mirrors are painted, non-mirrors normally are not.

3-Mirrors usually have plenty of matching color on both posts, non-mirrors do not.

Be sure to view the example photos of other Mirror car details on our other Mirror pages.

-

Mirror vs Non-Mirror

Any text here

-

-

Peach UV - Red fade -

Light Pink

UV - (Champagne Pink)

Info

-

What color is my mirror?

Mirror finish castings created by applying a laquer painted color over a very brightly plated jewelry type chrome finish.

Topper Toys used one of the largest and most prolific costume jewelry manufacturers in the United States and the world to produce their Mirror finished cars. This Providence, RI jewelry manufacturer was named Coro Jewelry. Coro which was 14 miles away from Crown. This process used what Coro called "Corochrome", which was a plating process that had been mostly used for costume jewlery. This type of finish is known to chip. And when they do chip, they tend to get large chips.

Why were they were made? Many stories are around, but according to a Topper salesman... they were originally intended to be salesman samples and TV props. As they were more expensive to make than the standard laquer painted cars, their cost could be reduced by making larger batches so they made full production run of them. Many of the cars were also used as employee gifts, as well as the salesman samples while the rest were carded and used like regular production cars found on the pegs or in sets(usually one of the gravity sets). No one knew they were special at the time as they were just what they were... toy cars.

How the Mirror finish was actually applied:

1. After the cars were cast. those with hoods, doors and springs were assembled, then were sent to Coro for finishing.

2. Coro runs them through a cleaning/decontamination process.

3. They are hung on a tree and electroplated by lowering them into a tank containing the proper solution of ingredients before electricity is applied to the process. Some times the hoods were up and sometimes not. Lowering them into the tank is sometimes referred to as "dipping".

4. This electro plating resulted in a bright silver /chrome finish. The orange peel effect that is sometimes seen is a result of poor electroplating. Many things can go wrong from the size of the particles to temperature used to lots and lots of things that result in an uneven plating.

5. After more rinsing/cleaning, they were lacquer spray painted.. possibly at Coro.... probably electrostatically as the paint spray patterns are different than what is on the standard Topper paint jobs. Also with and without the hoods sometimes sticking open.

6. Sent back to Topper for final assembly.

Lastly, the silver chrome plating does not fade, but the lacquer paint applied to them is susceptible to all the paint thickness and fading variations that regular paint has.

1. After the cars were cast. those with hoods, doors and springs were assembled, then were sent to Coro for finishing.

2. Coro runs them through a cleaning/decontamination process.

3. They are hung on a tree and electroplated by lowering them into a tank containing the proper solution of ingredients before electricity is applied to the process. Some times the hoods were up and sometimes not. Lowering them into the tank is sometimes referred to as "dipping".

4. This electro plating resulted in a bright silver /chrome finish. The orange peel effect that is sometimes seen is a result of poor electroplating. Many things can go wrong from the size of the particles to temperature used to lots and lots of things that result in an uneven plating.

5. After more rinsing/cleaning, they were lacquer spray painted.. possibly at Coro.... probably electrostatically as the paint spray patterns are different than what is on the standard Topper paint jobs. Also with and without the hoods sometimes sticking open.

6. Sent back to Topper for final assembly.

Lastly, the silver chrome plating does not fade, but the lacquer paint applied to them is susceptible to all the paint thickness and fading variations that regular paint has.

-

-

DARK PINK -------------- LIGHT PINK -------------- GOLD

Courtesy of Woody Itson

-

Topper - Mirror Dipped Finish

Color Comparisons

Color Comparisons

Copyright © 2024

JLToppers.com

All rights reserved.

The pictures and descriptions on this site may not be reused without obtaining prior expressed written consent permission from the site owner.

Johnny Lightning is a registered Trademark of Round 2 LLC. This site is

not affiliated with Round 2 LLC in any way.